Vacuum Sealer

Chamber Vacuum Sealer | SKU: SC-680LR

FEATURES:

Perfect for heavy duty applications

Stainless steel construction

PD-01 Basic Digital Control Panel

#304 Stainless Steel Construction

Flat Chamber for Easy Cleaning

Bladder Activated Sealing

Water Resistant Electrical Box (IP 56)

Durable Removable Aluminum Cushion Bar

Busch RA0040 (2HP) Vacuum Pump

Air Assist Sealing

6mm Seal Wire (standard) or Cut-Off (option)

Voltage: 220V

ETL, UL, NSF, CE, and CSA certified

Ships via LTL Freight only

Via special order

SC-680LR is truly a heavy-duty industrial vacuum chamber sealing machine. With features like all # 304 stainless steel construction, a flat working deck for easy cleaning and a robust Busch RA0040 (2HP) vacuum pump as standard the SC-680LR is ready to meet your heavy duty vacuum packaging needs. The SC-680LR has been ETL tested, certified and labeled as meeting UL and CSA safety standards as well as NSF sanitary standards. This means the SC-680LR is ready to go to work in any inspected facility.

Available options include larger vacuum pumps, particulate and moisture trap filters, to protect the vacuum system, per knife bag trim systems and many more. The standard PD-01 basic digital control panel allows the operator to set vacuum time, gas flush time (if your machine is equipped with the optional gas flush system), seal time and cooling time at the touch of a button and with accuracy due to the digital read out.

If your applications require more control features including recipe memory the optional PNC-01 microprocessor control panel may be just what you need. The PNC-01 allow the vacuum to be controlled via vacuum pressure or by time and allows multi-stage vacuum / gas flush operations (optional gas flush system required) just to name a few of the capabilities of this control system. For applications that require a temperature controlled seal system and / or a fully validate able control system the SC-680LR can be equipped with our Precise Seal PLC/HMI based control system. This system allows for the seal to be controlled via temperature or time as well as allowing for the vacuum to by very precisely controlled via vacuum pressure. Optional calibration ports are also available allowing a 3rd party calibration lab to easily calibrate and certify your machine.

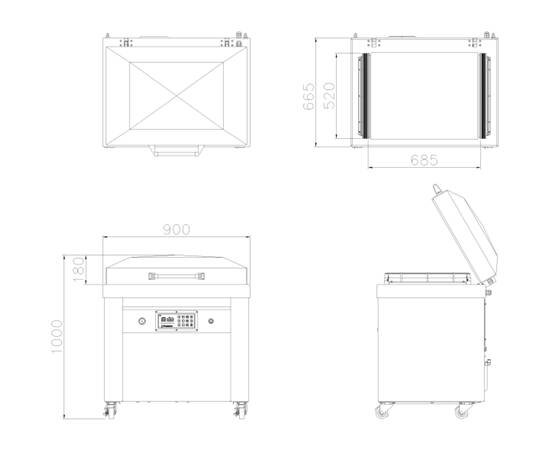

Specifications:

| Header 1 | Header 2 |

|---|---|

| Power Suppply | 220V / 3Ph / 60Hz / 15AMP |

| Vacuum Pump Capacity | 40m³/h (2HP/1Kw) |

| Seal Bar Length | 20.5" x 2 (520MM) |

| Distance Between Seal Bars | 26" (665MM) |

| Sealing Width | Standard: 6mm seal | Option: 3mm seal w/ electric cut off |

| Chamber Depth | 7" |

| Vacuum Chamber (W x L) | 35.8" x 26" |

| Dimensions | 35" x 26" x 39" |

| Weight (lbs) | 500 |